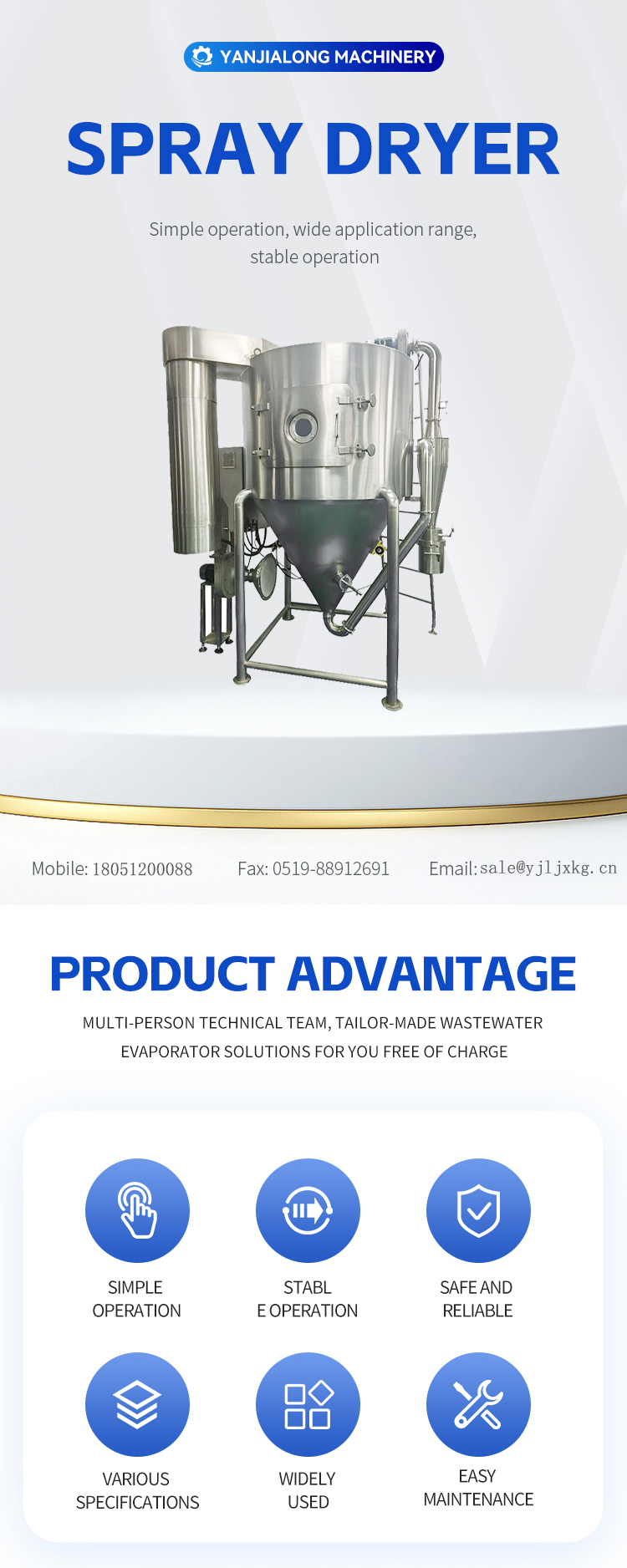

High Speed Centrifugal Phenol Formaldehyde PF Resin Spray Dryer

| Unit Price: | 20000~350000USD | Get Latest Price |

|---|---|

| Unit Price: | 20000~350000 USD |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Shanghai,Ningbo |

- Product Catalog

- Company List

Product Description

- Model No.: LPG

- Operation Pressure: Atmospheric Dryer

- Drying Medium: Inactive Gas

- Heating Mode: Transmission

- Movement Way: Combined

- Sprayer: Centrifugal

- Structure: Spraying Drier

- Operational Method: Continuous

- Appearance of Dried Sample: Pastes

- Type of Atomization: Gas Atomization

- Type of Flow: Contra-Flow

- Packaging: wooden cases

- Productivity: 5-1000kg/h

- Brand Name: yanjialong

- Place of Origin: china

- Supply Ability: 5-10 set/month

- Certification: ISO9001

- HS Code: 841939

Centrifuge spray dryer of formaldehyde resin,formaldehyde amino resin ,formaldehyde epoxy resin.spray equipment for formaldehyde resin,formaldehyde amino resin,formaldehyde epoxy resin

Specifications

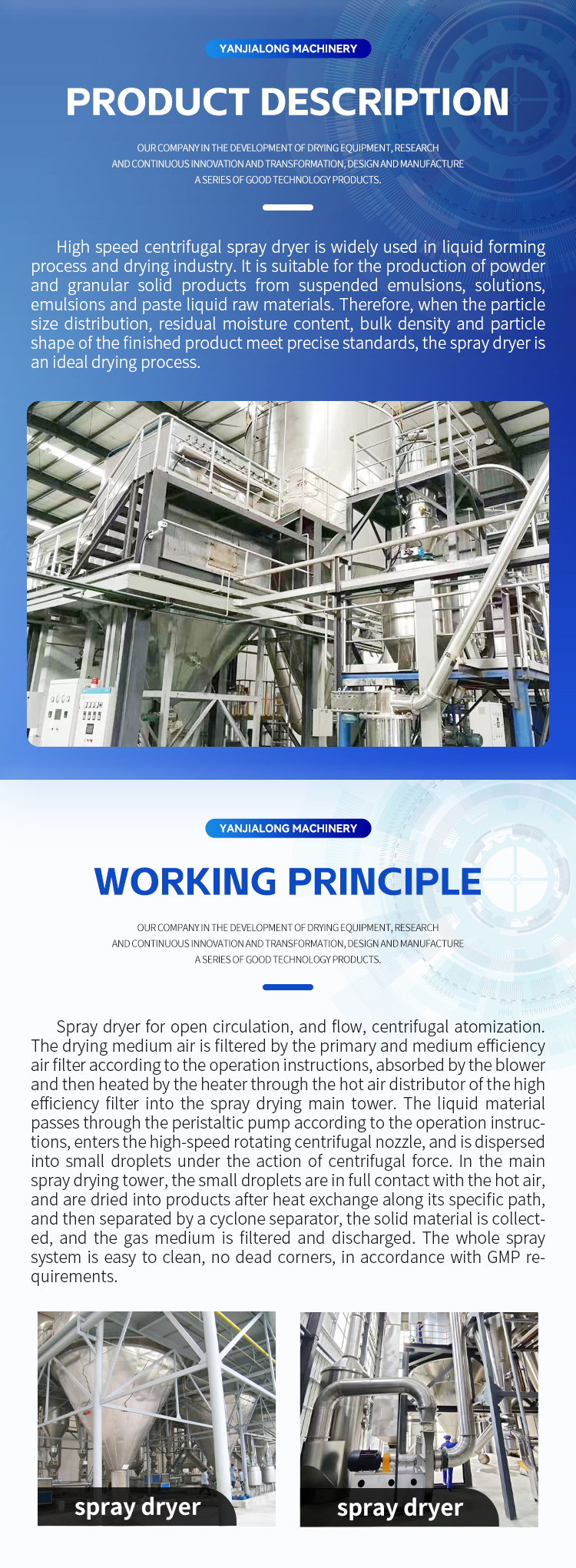

Work Principle Description

After filtering and heating, the air enters into the hot air distributor at the top of the centrifugal spray dryer, and the hot air will spirally and evenly goes into the drying chamber. The material liquid via high-speed centrifugal atomizer rotates into extremely thin vaporific liquid globule and parallelly flows with the hot air, and then the liquid will be dried into powdery products in a very short time (5-10 seconds). The waste gas after filtering will be expelled through the fan. For the wet organic solvent materials, the spray drying machine can be designed with closed cycle process. It can utilize cyclic nitrogen to dry the materials.

Machine Pictures

Application of Spray Dryer for PF resin

We are the spray dryer national stardard maker, our spray dryer is widely used for sheep blood, bovine(ox) blood, Pig blood etc.

With high drying efficiency, large production, low operation cost, good product quallity features, our spray dryer is welcomed by all home and aborad customers.

Features

Our PF resin spray dryer machine, which can instantly evaporate 95%-98% moisture of materials, is perfect for drying thermosensitive materials. Typically, the drying time is 5 to 15 seconds.

The dried products have the advantages of high purity, great fluidity and solubility.

This spray drying machine is simple to operate and eliminates the need for grinding and screening after drying.

Technical Specifications of Centrifugal Spray Drying Machine

|

Item/Model |

LPG |

|||||||||

|

5 |

25 |

50 |

100 |

150 |

200-2000 |

|||||

|

Inlet temperature(℃) |

≤350 |

|||||||||

|

Outlet temperature (℃) |

80-90 |

|||||||||

|

Max. moisture evaporation (kg/h)* |

5 |

25 |

50 |

100 |

150 |

200-2000 |

||||

|

Drive type of centrifugal spray nozzle |

Compressed air drive |

Mechanical drive |

|||||

|

Rotation speed |

25000 |

22000 |

21500 |

18000 |

18000 |

15000 |

|

|

Diameter of spray disk(mm) |

50 |

102 |

108 |

108 |

150 |

180-340 |

|

|

Heat source |

Electricity |

Electricity |

Electricity |

Electricity + steam |

Electricity |

Depending on the user |

|

|

Max. electric heating power (kw) |

8 |

31.5 |

60 |

81 |

99 |

|

|

|

Outline dimensions L×W×H |

1.8×0.93×2.2 |

3×2.7×4.26 |

3.7×3.2×5.1 |

4.6×4.2×6 |

5.5×4.5×7 |

According to actual situation |

|

|

Dry powder recovery (%) |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

|

China Jiangsu

Min. Order:1 Set/Sets

Min. Order:1 Piece/Pieces

Yanjialong Machinery Technology (Jiangsu) Co., Ltd. is a production-oriented manufacturer engaged in the research, development and manufacturing of drying equipment and granulation machinery. It is currently a domestic enterprise that produces a wide variety of drying equipment with complete specifications. Our company continues to innovate and transform in the development and research of drying equipment, and has designed and manufactured a series of products with excellent technology. According to the needs of the market, we have developed more than 40 drying, granulating, mixing and dust removal series. The products are widely used for drying and dehumidifying industrial raw materials or products in pharmaceutical, chemical, food, light industry and other industries. Customers are welcome to bring materials for testing and inspection. Our company is located in Changzhou, a beautiful water town in the south of the Yangtze River and an industrial star city. It is located in the economic development belt of Shanghai and Nanjing, with pleasant climate and convenient transportation. The company has strong technical force, complete testing system and strict management system. We warmly welcome new and old customers and friends from all walks of life at home and abroad to visit us for guidance and work together to create a better future!

Basic Information

- Company Name:

Yanjialong Machinery Technology (Jiangsu) Co., Ltd.

- Representative:

lu wenguang

- Business Type:

Manufacturer

- Product/Service:

MVR evaporator , Low temperature evaporator , Sludge dryer , wastewater evaporator , Power plant wastewater treatment , spray dryer

- No. of Total Employees:

N/A

- Capital (Million US $):

108,0000RMB

- Year Established:

2000

- Product Range:

Chemical Machinery & Equipment , Evaporator

- Certificate:

Manufacturer

- Company Address:

Jiaoxi,Zhenglu Town, Tianning District

Trade & Market

- Total Annual Sales Volume (Million US $):

US$10 Million - US$50 Million

- Export Percentage:

11% - 20%

- Total Annual Purchase Volume (Million US $):

US$10 Million - US$50 Million

- Main Markets:

Worldwide

Factory Information

- No. of Production Lines:

12

- No. of R&D Staff:

11 -20 People

- No. of QC Staff:

5 -10 People

- OEM Services Provided:

YES

- Factory Size (Sq.meters):

Above 100,000 square meters

- Factory Location:

Shunehe Road68 ,Jiaoxi, Zhenlu Town, Wujin District, Changzhou City, Jiangsu Province, China

Other products from this company MoreEmail to this supplier

Categories: LPG Centrifugal Spray Dryer

Business type:Manufacturer

Certification:ISO9001,ISO14001,CEOEM service:YES

Our Products Range