aluminum shock head

| Unit Price: | Get Latest Price |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 100 Bag/Bags |

| Delivery Time: | 15 Days |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

- Product Catalog

- Company List

Product Description

- Model No.: lk-ak520

- Packaging: paper wrapper

- Productivity: 10000

- Brand Name: auking

- Place of Origin: china

- Supply Ability: 20000

- Certification: iso9001-20008

- HS Code: 87061300

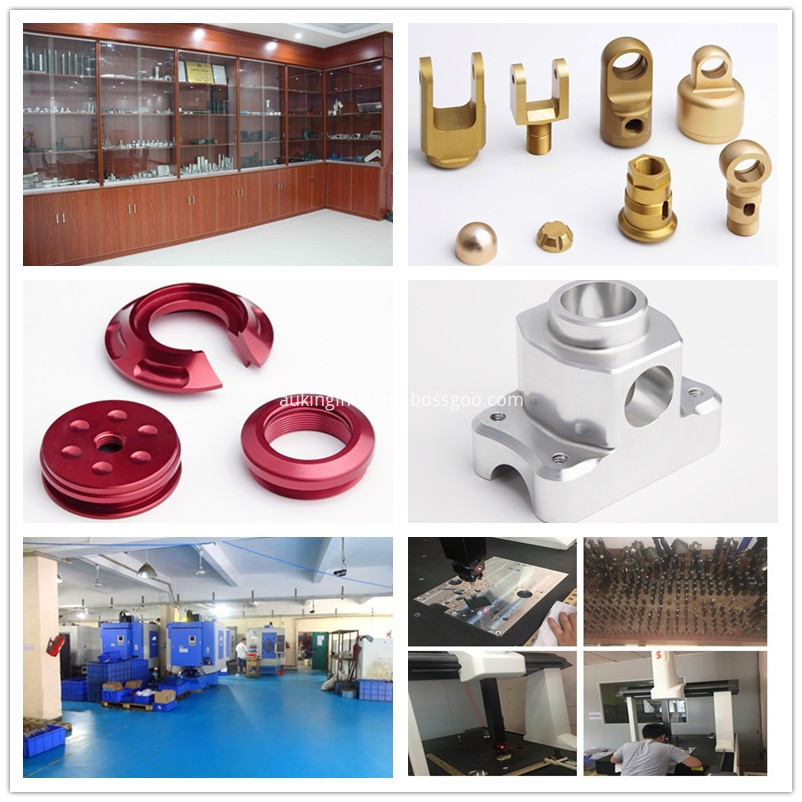

Auking Robotic parts suspension parts

AUKING Making A Prototype .this chart specifies the tolerances you can expect when working with many kinds of injection molding plastics. Want to know still more? Contact us today for a free quotation and d team will select the most appropriate and cost-effective way proposed to customers to build rapid tooling, based on customers's required lead-time, production volumes, tolerance requirements, material specifications, product applications and project budgets. With the state-of-art tooling equipments, we offer clients with high quaity rapid moulds with fast turn around.consistent and accurate method of producing prototypes from actual production-grade materials. T How cnc turned parts MTB bike parts cnc milled partsThis gives the most complete picture of the total part, which is helpful for generating an accurate quotation.The more information we have from your side the faster and more efficiently we can get to work making your prototype or low-volume production part. cnc machining parts with every cut or pass. Could be an extra millimeter, or too short by a millimeter or some fraction thereof. Useful information: What`s true for the mach expand and contract with temperature and moisture, so good design means allowing for this natural movement. And draft angles are necessary cnc milled parts cnc machineing parts his makes it possible to use many materials, including plastics and metals, and also undercuts and double bended surfaces are feasible. CNC Swiss machines were originally designed to produce small thin parts, today CNC Swiss machines are capable of much more. M&R Engineering`s CNC Swiss lathes have sub spindles allowing the simultaneous machining of the front and back side of the part.

Surface treatment: color anodizing,powder coating, Nickel plating, chrome plating, plating, painting, zinc plating, black, E-coating, anodizing, polishing, gold-plating, silver plating, copper plating, copper-tin alloy, hot-dip galvanizing, oxidation, electrophoresis, wire drawing and more.

Tolerance: ±0.01mm

Certificate: ISO9001:2008

CNC machining cnc turning parts detail show:

Precision Milled Parts VehiclePrecision Milled Parts Vehicle

Sample delivery: 7-15working days,base on the customer's requirement.

File formats: Solid Works STP,Pro/Engineer, Auto CAD(DXF,DWG), PDF,TIF etc.

Applications: Household appliances, office equipment, construction Medical devices, electrical equipment, furniture, auto parts and more

Packaging: inner plastic bag, outer carton box, and we can also pack products according to your requirements

Testing equipment: Projecting apparatus, salt spray test, durometer, and coating thickness tester

Related Products:

Precision Aluminium Gear Housing

Producing equipment:

Milling machine COYO/ALSGS and CY-L-90

Other machines including spring machine Jinju and 502S, shaft machine liqiang, auto lathes Libo and XB, CNC machine SHENGYU, SYX42, inclinable press machine World and J23-80/ J23-65A/J23-16,Wire cutting machine Deren and DK7740, continuous hot-wind tempering furnace Sanli and RJC210, tapping machine Dongrong/EF, grinder machine DA Shuang Yang and M230-2, lathe machine C6233, screw machine Hexing/SX and H series and more

Auking Industry

Testing equipment:

Projecting apparatus, salt spray test, durometer, and coating thickness tester

china

Auking Precision Manufacturing is a precision engineering manufacturer specialized in high-quality CNC machined components and CNC precision machined parts. We have rich experience in working with a wide variety of materials including stainless steel, aluminum, brass, copper and plastic, and providing customized parts for a variety of industrial and commercial uses, such as electronics, aircraft, automobile, ATV, marine, medical and other fields.

We provide engineering support to help you develop the best component solutions for your needs. With many years of experience in producing motorcycle shock absorber components and also supplying all kinds of racing parts and camera housings, we have the skills to play a dynamic part in your success.

Basic Information

- Company Name:

DongGuan Auking Industry Co.,Ltd.

- Representative:

Xinhong Cao

- Business Type:

Manufacturer

- Product/Service:

CNC Machining , Precision Machining , CNC Parts , CNC Service , CNC Machining Parts , Shock Absorber Parts

- No. of Total Employees:

101~200

- Capital (Million US $):

500000RMB

- Year Established:

2003

- Product Range:

Mobile Phone Bags & Cases , Other Hardware

- Certificate:

Manufacturer

- Company Address:

Hong da Industrial Park,Ge keng Industrial Zone,Heng Li Town

Trade & Market

- Total Annual Sales Volume (Million US $):

US$1 Million - US$2.5 Million

- Export Percentage:

51% - 60%

- Total Annual Purchase Volume (Million US $):

Below US$1 Million

- Main Markets:

Americas , Europe , North Europe , East Europe , Oceania , Other Markets

Factory Information

- No. of Production Lines:

5

- No. of R&D Staff:

11 -20 People

- No. of QC Staff:

5 -10 People

- OEM Services Provided:

yes

- Factory Size (Sq.meters):

1,000-3,000 square meters

- Factory Location:

Hong da Industrial Park,Ge keng Industrial Zone,Heng Li Town

Categories: CNC Milled Parts

Business type:Manufacturer

Certification:BRC,BSCI,FSC,GB,GMP,GSV,ISO/TS16949,ISO10012,ACS,AZO Free,CE,EEV,FCC,Oeko-Tex Standard 100,REACH,RoHS,SSA,TUV,UL,VDEOEM service:yes