high precision suspension ring

| Unit Price: | USD 10 / Bag/Bags |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,FCA |

| Min. Order: | 100 Bag/Bags |

| Delivery Time: | 15 Days |

| Transportation: | Ocean,Land,Air |

| Port: | Shenzhen |

- Product Catalog

- Company List

Product Description

- Model No.: LK-AK2543

- Packaging: paper

- Productivity: 20000

- Brand Name: auking

- Place of Origin: china

- Supply Ability: 20000

- Certification: iso9001-2008

- HS Code: 87061300

Related Products:

Auking Industry

Shan'Xi

Min. Order:10

Baoji, Shaan'xi

Min. Order:100

Shaanxi,Baoji

Min. Order:10

shaanxi,Baoji

Min. Order:10

Shannxi

Min. Order:10

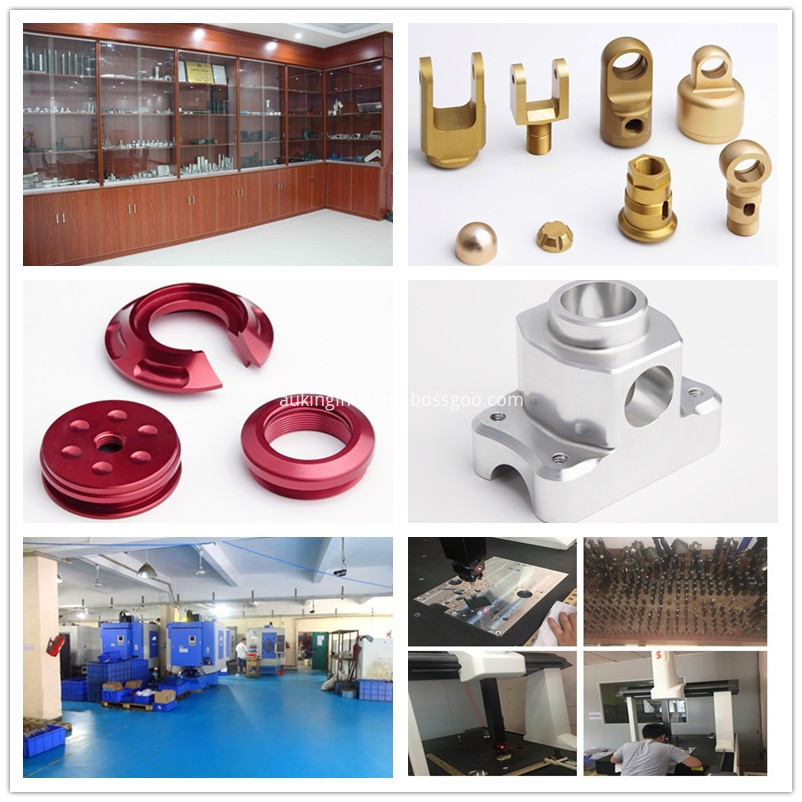

DongGuan Auking Industry Co.,LtdAuking Precision Manufacturing is a precision engineering manufacturer specialized in high-quality CNC machined components and CNC precision machined parts. We have rich experience in working with a wide variety of materials including stainless steel, aluminum, brass, copper and plastic, and providing customized parts for a variety of industrial and commercial uses, such as electronics, aircraft, automobile, ATV, marine, medical and other fields.

We provide engineering support to help you develop the best component solutions for your needs. With many years of experience in producing motorcycle shock absorber components and also supplying all kinds of racing parts and camera housings, we have the skills to play a dynamic part in your success.

Basic Information

- Company Name:

DongGuan Auking Industry Co.,Ltd.

- Representative:

Xinhong Cao

- Business Type:

Manufacturer

- Product/Service:

CNC Machining , Precision Machining , CNC Parts , CNC Service , CNC Machining Parts , Shock Absorber Parts

- No. of Total Employees:

101~200

- Capital (Million US $):

500000RMB

- Year Established:

2003

- Product Range:

Mobile Phone Bags & Cases , Other Hardware

- Certificate:

Manufacturer

- Company Address:

Hong da Industrial Park,Ge keng Industrial Zone,Heng Li Town

Trade & Market

- Total Annual Sales Volume (Million US $):

US$1 Million - US$2.5 Million

- Export Percentage:

51% - 60%

- Total Annual Purchase Volume (Million US $):

Below US$1 Million

- Main Markets:

Americas , Europe , North Europe , East Europe , Oceania , Other Markets

Factory Information

- No. of Production Lines:

5

- No. of R&D Staff:

11 -20 People

- No. of QC Staff:

5 -10 People

- OEM Services Provided:

yes

- Factory Size (Sq.meters):

1,000-3,000 square meters

- Factory Location:

Hong da Industrial Park,Ge keng Industrial Zone,Heng Li Town

Other products from this company MoreEmail to this supplierCategories: CNC Milled Parts

Business type:Manufacturer

Certification:BRC,BSCI,FSC,GB,GMP,GSV,ISO/TS16949,ISO10012,ACS,AZO Free,CE,EEV,FCC,Oeko-Tex Standard 100,REACH,RoHS,SSA,TUV,UL,VDEOEM service:yes